Provide you with the latest enterprise and industry news.

1. Gas Flow Control:

At the core of temperature regulation in cooking home equipment lies the gas oven valve's fundamental characteristic—controlling the float of herbal gas or propane to the oven burner. The valve serves as the gateway for gas, allowing customers to modulate the flame's depth via adjusting the valve's function. This manipulate is essential for accomplishing the desired cooking temperatures required for numerous dishes.

2. Thermostatic Regulation:

Gas oven valves are frequently paired with a thermostat, a temperature-sensing device that constantly monitors the oven's internal temperature. This integration enables particular temperature law. When the oven's temperature deviates from the set point, the thermostat sends signals to the fuel valve, instructing it to both boom or decrease the fuel drift. This dynamic interplay guarantees that the oven continues a constant temperature during the cooking technique.

3. Temperature Knob or Control Panel Adjustment:

User-friendly interfaces, together with temperature knobs or virtual control panels, permit customers to regulate the cooking temperature in step with their recipes or preferences. Turning the knob or inputting temperature settings triggers the fuel oven valve to respond consequently. This direct and intuitive manipulate mechanism empowers customers to customise the oven's temperature effects.

4. Safety Features:

Safety is paramount in gas ovens, and fuel oven valves are prepared with capabilities to mitigate potential risks. The inclusion of a thermocouple is one such safety degree. This device senses the presence of a flame. If the flame extinguishes by chance, the thermocouple sends a sign to the fuel valve to close off the fuel deliver, stopping the discharge of gas with out combustion and lowering the risk of gas leaks.

5. Pilot Light or Ignition System:

Traditional gas ovens regularly depend on a pilot light for ignition. The fuel valve continuously releases a small quantity of gasoline to preserve a pilot flame. When the oven is grew to become on, this flame serves because the ignition source for the primary burner. While electronic ignition systems have grow to be greater common, they nonetheless involve the fuel valve in controlling the ignition process, ensuring a continuing begin to the cooking cycle.

6. Bimetallic Coil Mechanism:

Some fuel oven valves incorporate a bimetallic coil mechanism within the thermostat. This coil responds to temperature adjustments through increasing or contracting. As it movements, it controls the fuel valve's function, dictating the amount of gas go with the flow. This dynamic interaction among the bimetallic coil and the fuel valve ensures a responsive and correct adjustment of the oven's warmness output.

7. Modulating Gas Valve Technology:

Advancements in gasoline oven valve era have brought about the creation of modulating features. This technology enables the gas valve to make diffused adjustments to the gas flow. The result is greater specific temperature control, reducing the likelihood of temperature fluctuations at some point of cooking. Modulating fuel valve era enhances the oven's functionality to hold a stable and correct temperature, mainly critical for precision cooking.

8. Preheat Function:

Gas ovens include a preheat characteristic, a process made possible through the gasoline oven valve. When customers provoke the preheat setting, the gasoline valve allows an improved flow of gas to the burner. This surge in gasoline float rapidly increases the oven's temperature to the desired degree. Once the preheat segment is complete, the fuel valve adjusts the float to keep the set cooking temperature, ensuring a continuing transition from preheating to cooking.

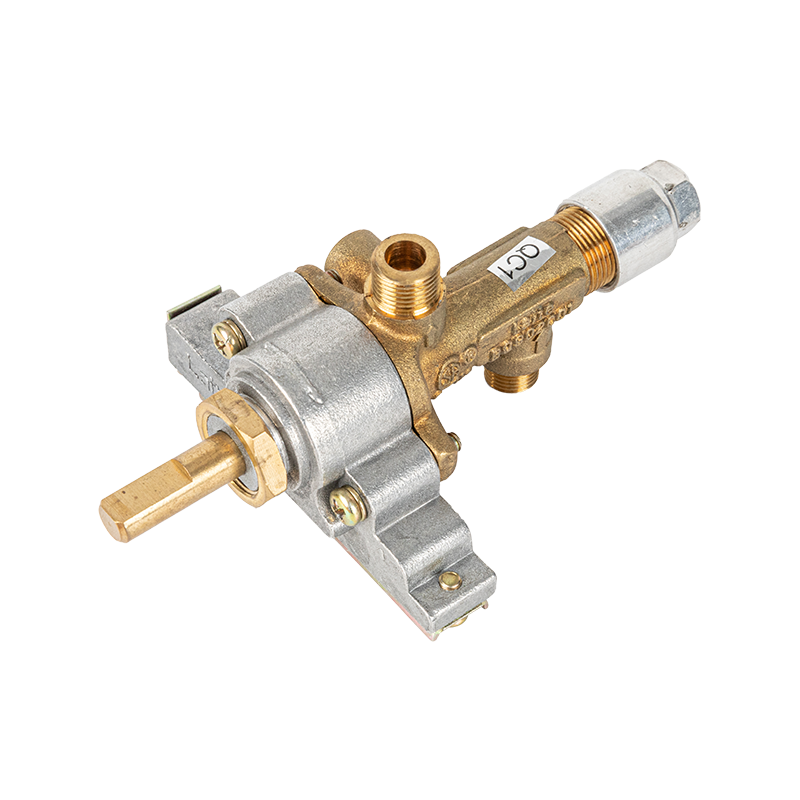

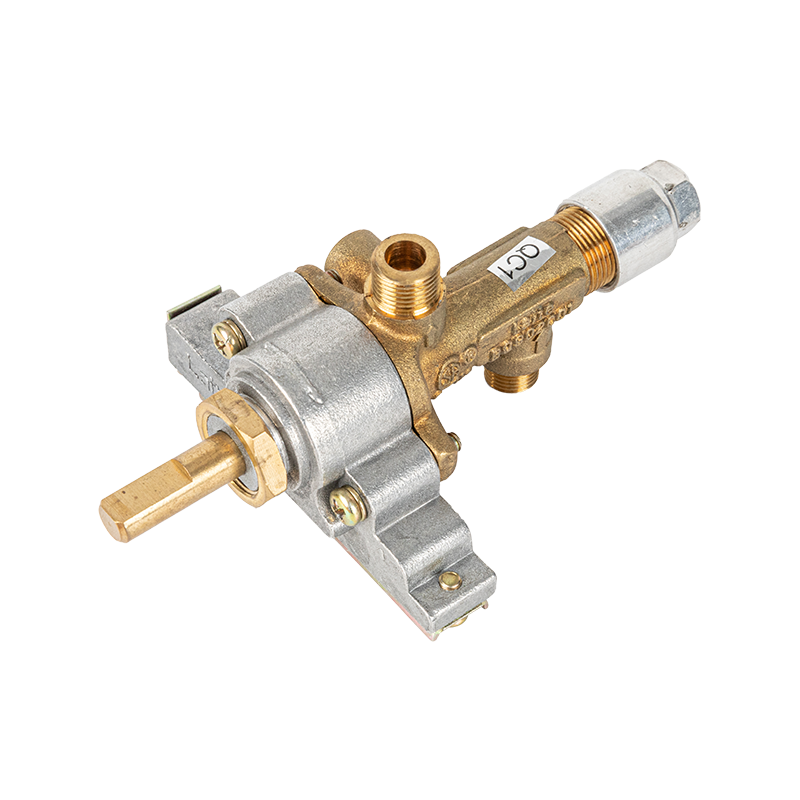

Gas Oven Valve

Gas Oven Valve

EN

EN 英语

英语 中文简体

中文简体