Provide you with the latest enterprise and industry news.

2.Thermal Protection: Thermal protection is another critical safety feature incorporated into blender motors to prevent overheating and maintain safe operating temperatures. This feature typically involves temperature sensors or switches positioned within the motor housing to monitor its temperature during operation. If the motor temperature exceeds a predetermined threshold, indicating potential overheating, the thermal protection system activates and interrupts power to the motor. This automatic shutdown prevents further temperature escalation and allows the motor to cool down to a safe level. By preventing overheating, thermal protection safeguards the motor's components from damage, extends its lifespan, and reduces the risk of electrical hazards. It is an essential safety measure that ensures reliable and safe operation of blender motors, particularly during extended or intensive use.

3.Safety Interlock System: A safety interlock system is designed to prevent blender motors from operating unless all components are correctly assembled and securely in place. This feature typically includes switches or sensors that detect the positioning of the blender jar or pitcher and its lid. If the blender is not fully assembled or if the lid is not securely attached, the safety interlock system prevents the motor from activating. This prevents accidents caused by accidental activation of the motor when the blender is not properly assembled, reducing the risk of spills, splatters, or injuries to users. The safety interlock system enhances user safety by ensuring that the blender operates only when all components are securely in place, minimizing the potential for accidents or malfunctions during operation.

4.Ground Fault Circuit Interrupter (GFCI): In electrical blender models, a ground fault circuit interrupter (GFCI) is a safety device designed to protect against electrical shocks in the event of a ground fault or short circuit. This feature is particularly important in environments where water is present, such as kitchens or bathrooms, where blenders are commonly used. The GFCI continuously monitors the electrical current flowing through the motor and detects any imbalances that indicate a potential ground fault. If a fault is detected, the GFCI quickly interrupts power to the motor, preventing electrical shocks or injuries to users. By providing an additional layer of protection against electrical hazards, the GFCI enhances the safety of blender motors, particularly in wet or damp environments where the risk of electrical accidents is higher.

5.Non-Slip Feet: Non-slip feet or suction cups are features commonly found on blender bases to provide stability and prevent the appliance from sliding or tipping over during operation. These feet are typically made from non-skid materials such as rubber or silicone, which grip the countertop or surface to keep the blender securely in place. By preventing movement or instability, non-slip feet reduce the risk of accidents caused by the blender shifting or tipping during operation. This enhances user safety by ensuring that the blender remains stable and secure, even when processing heavy or thick ingredients at high speeds. Non-slip feet are an essential safety feature that contributes to the overall stability and reliability of blender motors, providing users with confidence and peace of mind during use.

6.Durable Housing: The motor housing of blender motors is constructed from durable materials such as metal or high-impact plastic to provide protection against impact damage and ensure long-term durability. This sturdy housing encases the motor's internal components, shielding them from external impacts or accidents that could cause damage or injury. The durable housing also helps to contain any potential hazards within the motor, reducing the risk of exposure to moving parts or electrical components. Additionally, the housing is designed to withstand the rigors of regular use and cleaning, ensuring that the motor remains functional and safe over time. By providing a robust protective barrier, the durable housing enhances the safety and reliability of blender motors, offering users peace of mind during operation.

7.Easy-to-Clean Design: While not traditionally considered a safety feature, the design of blender motors with easy-to-clean features contributes to safe operation by facilitating regular maintenance and preventing the buildup of food residues or contaminants that could compromise motor performance or pose health risks. Blender motors with removable parts or smooth surfaces are easier to clean and sanitize, reducing the risk of bacterial growth or contamination. By promoting cleanliness and hygiene, these design features help maintain optimal motor performance and prevent potential safety hazards associated with unclean or contaminated equipment. Easy-to-clean design features are an essential aspect of blender motor safety, ensuring that the appliance remains hygienic and safe for use by minimizing the risk of foodborne illnesses or equipment malfunctions.

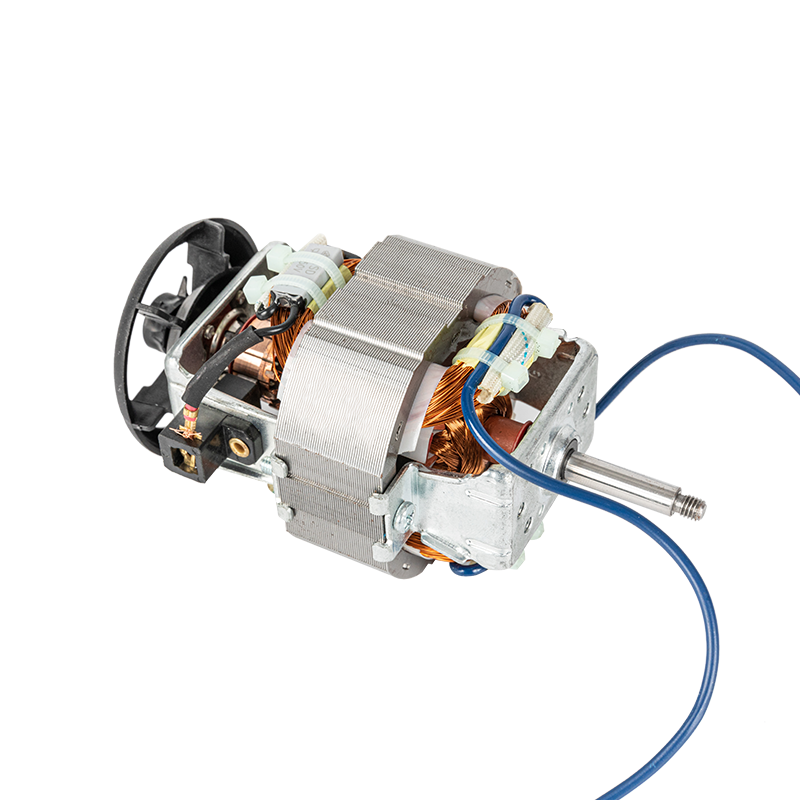

Blender Motor

EN

EN 英语

英语 中文简体

中文简体